Tracking the EV battery factory construction boom across North America | TechCrunch

[ad_1]

The onshoring of battery manufacturing for EVs started as a trickle through the COVID-19 pandemic. Now it’s a tsunami.

In 2019, simply two battery factories have been working in the US with one other two underneath building. At the moment, there are about 30 battery factories both deliberate, underneath building or operational within the nation.

U.S. President Joe Biden’s Inflation Reduction Act, signed into regulation August 16, 2022, may not have been the preliminary catalyst behind the onshoring battery manufacturing unit development. However it did assist open the spigot and speed up the tempo of manufacturing unit tasks — to not point out sparking a climate tech arms race with the EU. One 12 months later, we’re right here to make sense of it.

China lengthy managed the availability and manufacture of lithium-ion batteries. The nation’s grip on that offer chain started to loosen after automakers, hesitant to repeat the chip scarcity disaster that hampered manufacturing through the pandemic, started promising to construct EVs and batteries nearer to house in 2021.

What has adopted is a wave of automakers and battery makers — overseas and home — pledging to supply North American-made batteries earlier than 2030.

IRA carrots and sticks

That’s as a result of the IRA is rife with incentives for automakers and customers to supply domestically – a concerted effort to finish the U.S.’s reliance on China for batteries, whereas concurrently assembly Biden’s purpose to make 50% of all new automobile gross sales within the U.S. electrical or hybrid by 2030. Autos can qualify for the complete $7,500 EV tax credit score in the event that they meet sure battery sourcing and manufacturing pointers.

The IRA requires that 60% of the worth of battery parts be produced or assembled in North America in 2024 to qualify for half of the tax credit score, $3,750. That share will improve to 100% beginning in 2029. To get the remaining half, 50% of the worth of essential supplies have to be sourced from the U.S. or a free commerce settlement nation in 2024 and 80% from 2027 to 2032.

The IRA additionally consists of superior manufacturing credit that give the producer a payout from the Treasury. Under Section 45X, the manufacturing of battery cells qualify for a credit score of $35 per kilowatt-hour of capability, and the manufacturing of battery modules qualify for $10 per kilowatt-hour. Firms may also be reimbursed 10% of the prices incurred because of the manufacturing of electrode lively supplies, just like the cathode and anode.

Automakers and battery producers have collectively invested and promised to take a position near $100 billion in constructing home cell and module manufacturing. Collectively, these firms promise to ship an annual capability of over 1,200 gigawatt-hours earlier than 2030, if every manufacturing unit reaches most capability. That’s roughly sufficient batteries for 18 million EVs, based mostly on earlier Tesla predictions that say about 100 GWh capability can energy round 1.5 million EVs.

The funding into producing batteries within the U.S. and Canada modifications weekly, so we’ve began monitoring these guarantees.

Automakers investing in home battery manufacturing

TechCrunch created a useful map exhibiting the placement of every battery manufacturing unit plus some fundamental info, together with deliberate capability. For these searching for extra particulars and context, scroll right down to examine every producer’s deliberate or operational battery factories. Or click on on a location on the map for a pop as much as seem. Click on extra info for a shortcut to that part.

Map credit score: Miranda Halpern

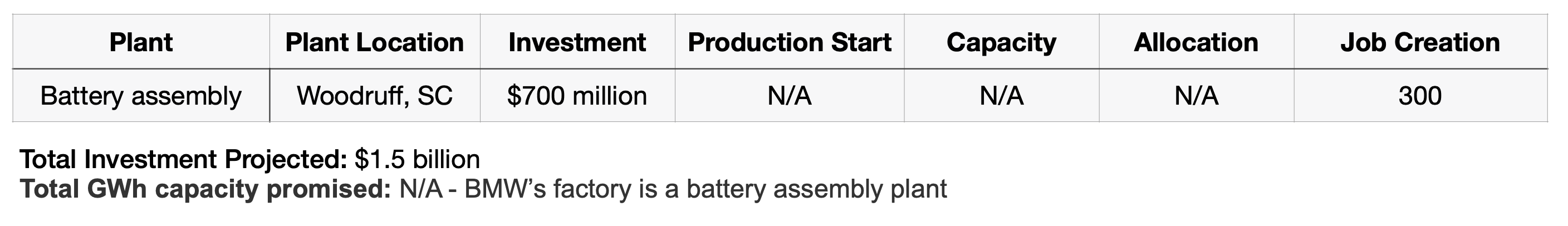

BMW

In October 2022, BMW announced a $1.7 billion funding within the U.S. that will see its Spartanburg, South Carolina plant readied for the manufacturing of EVs and the buildout of a battery meeting facility in close by Woodruff. The automaker has not introduced the manufacturing begin date for the plant but, nor which EVs will probably be produced there. BMW’s Spartanburg manufacturing unit is at present the place its sports activities utility and crossovers are constructed, together with the X3, X4, X5, X6, X7 and XM.

BMW additionally partnered up with battery-maker AESC (previously Envision AESC) to take a position further funds in a battery cell plant in Florence, SC (extra on that within the AESC part). The AESC plant will produce BMW’s new sixth-generation spherical lithium-ion battery cells for Plant Spartanburg EVs. Groundbreaking on each the Woodruff and Florence services occurred in June.

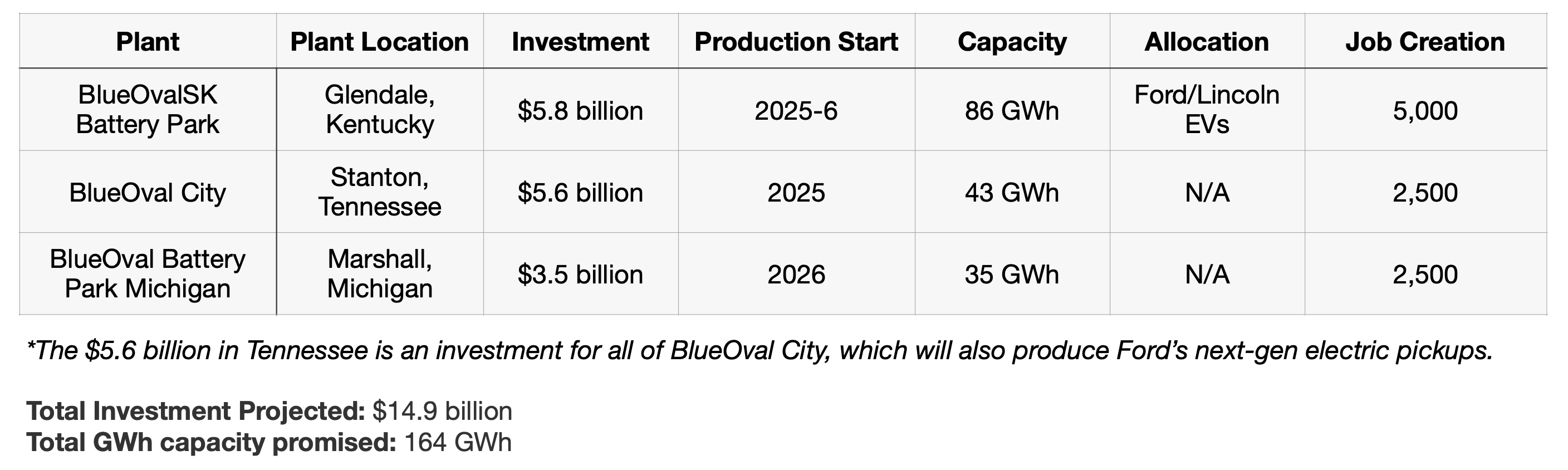

Ford

In September 2021, Ford created a three way partnership with South Korean battery maker SK On. The purpose of the JV, known as BlueOval SK, is to construct three battery crops in the US. Two are positioned in Kentucky; the third manufacturing unit in Tennessee will probably be co-located with a Ford meeting plant, which can produce the automaker’s second-generation electrical truck, code named Challenge T3.

Ford and SK On just lately secured a $9.2 billion mortgage from the U.S. Division of Vitality to assist finance the development of the three battery factories in Kentucky and Tennessee.

Ford can also be building a lithium iron phosphate plant in Michigan. Chinese language battery maker CATL is licensing its expertise to Ford as a service supplier on a contractual foundation. Which may change sooner or later, although, as Ford has now attracted the ire of Home Republicans who’re probing the automaker’s relationship with the Chinese language battery firm.

In the meantime in Canada, Ford said in April that it might flip its 70-year-old Oakville facility in Canada into an meeting plant for its next-gen EVs. The $1.34 billion (CAD $1.8 billion) improve will embody a 407,000-square-foot battery meeting plant that can use cells and arrays from Ford’s Kentucky plant and switch them into packs. These packs will then be put in into the EVs produced on the Oakville plant.

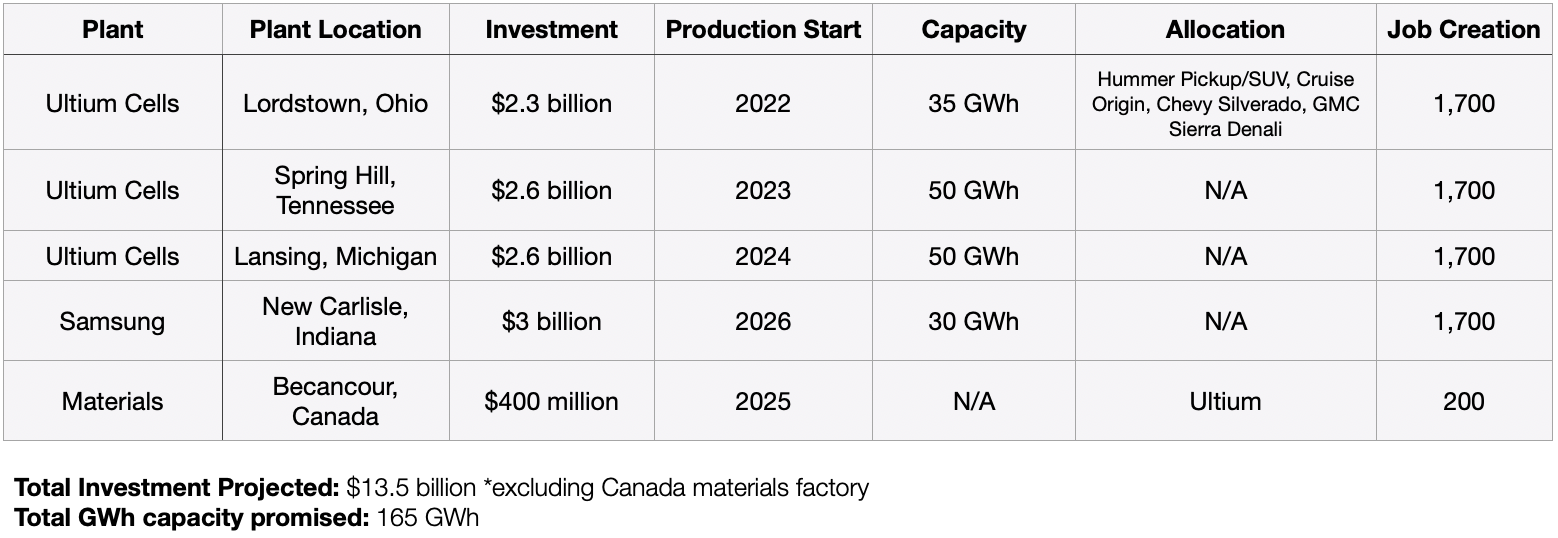

Normal Motors

Normal Motors goals to have three complete battery crops within the U.S. by way of its three way partnership with LG Chem, named Ultium Cells. That three way partnership secured in December 2022 a $2.5 billion mortgage from the federal government to assist fund its battery manufacturing unit tasks.

Normal Motors additionally introduced a JV with Samsung SDI in April to construct a new battery plant in the United States.

GM isn’t simply centered on quantity manufacturing. The automaker has additionally partnered with startup SolidEnergy Systems in 2021 to construct a prototyping facility in Woburn, Massachusetts. The purpose was to construct a high-capacity, pre-production lithium-ion battery this 12 months.

“We proceed to make progress on lithium-metal, each by way of our personal labs and with exterior collaborators. In truth, our R&D workforce, working with SES, has already demonstrated a 1,000 Wh/L lithium-metal battery with sturdiness higher than 250,000 simulated check miles.”

Exterior of the U.S., GM is engaged on taking management of battery supplies provide chain, as nicely. The corporate partnered in March 2022 with South Korea’s Posco Chemical to construct a $400 million battery supplies facility in Canada. The plant will produce cathode lively supplies.

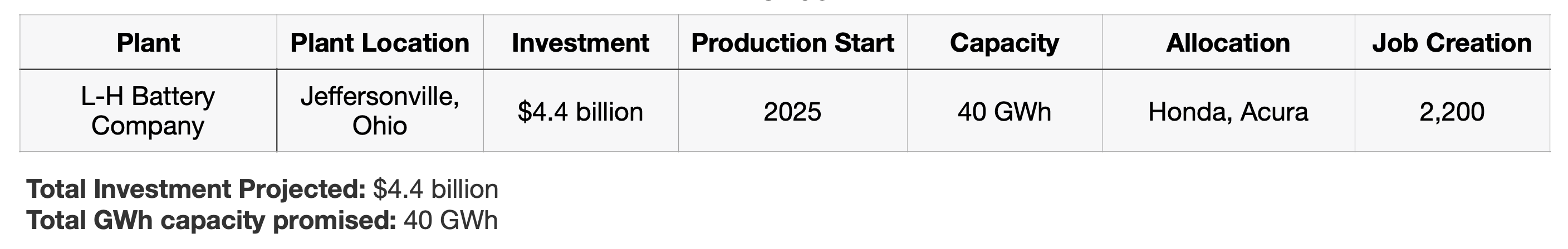

Honda

In August 2022, Honda introduced its joint venture with South Korea’s LG Vitality Options to produce the North American market with a “pouch sort” battery cells. The ability in Ohio will produce each cells and modules.

The automaker has additionally made strides to safe battery useful resource recycling channels and has agreements with companies together with Ascend Components, Cirba Options and Posco Holdings.

Honda’s engine plant in Anna, Ohio can also be within the technique of being retooled so as to add manufacturing of casing for battery modules that can energy Honda and Acura EVs made in Ohio.

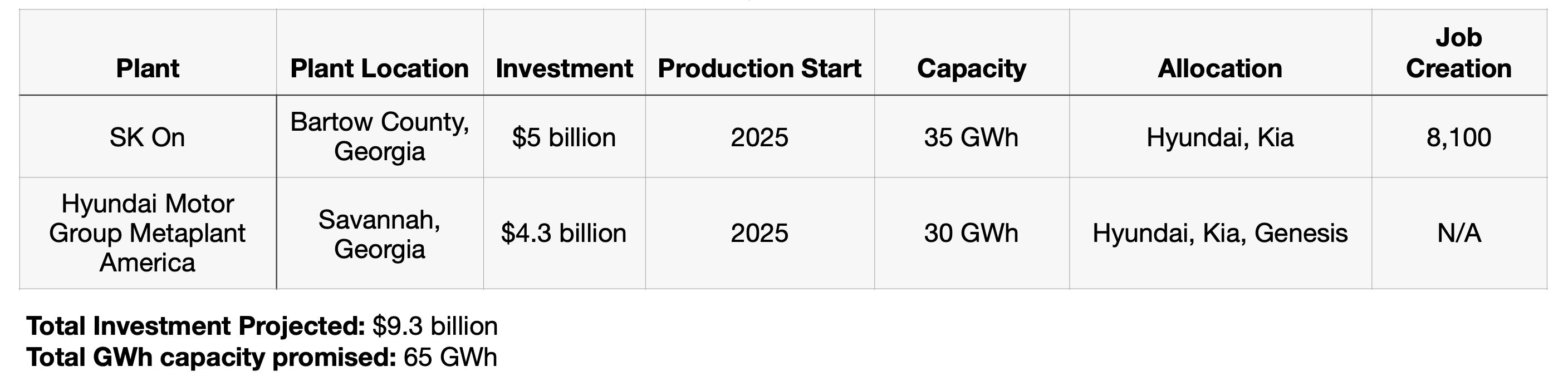

Hyundai

In April 2023, Hyundai and SK On approved plans to arrange a three way partnership to construct a $5 billion battery plant in Bartow County, Georgia. The next month, Hyundai and LG Vitality Answer shaped one other JV to construct a battery cell manufacturing unit close to Savannah, Georgia.

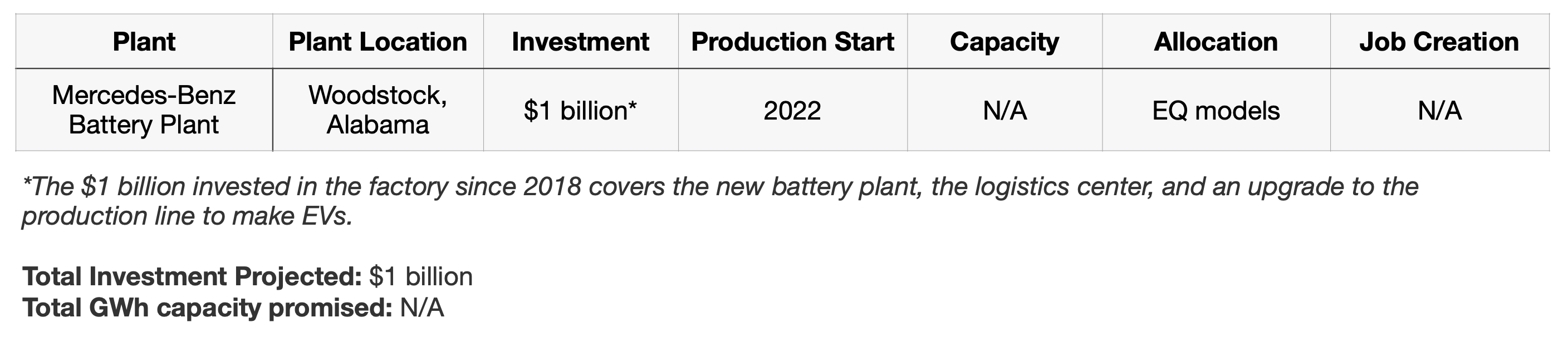

Mercedes-Benz

Mercedes-Benz opened a battery plant at its present manufacturing facility in Alabama in 2022. That summer season, the plant additionally turned the manufacturing website for the automaker’s totally electrical EQS SUV. The Alabama facility can also be assembling the EQE SUV, with the Maybach EQS SUV to comply with this 12 months, in keeping with a spokesperson from the corporate.

Mercedes can also be working with Sila, a next-gen battery supplies firm, to include Sila’s battery chemistry into batteries as an choice for patrons of the upcoming G-Class. Sila replaces the graphite in a battery cell with silicon, and is within the technique of scaling up at its new Washington state facility. The businesses are focusing on mid-decade for a range-extended model of the G-class.

Rivian

Rivian hasn’t outright dedicated to constructing its personal batteries in North America. The corporate is hoping to construct a massive EV production facility in Georgia, which could embody a cell manufacturing facility, but in addition may not. Rivian hasn’t confirmed.

A spokesperson advised TechCrunch the corporate expects a proper groundbreaking on the Georgia EV facility later this 12 months or early subsequent, with begin of manufacturing slated for 2026.

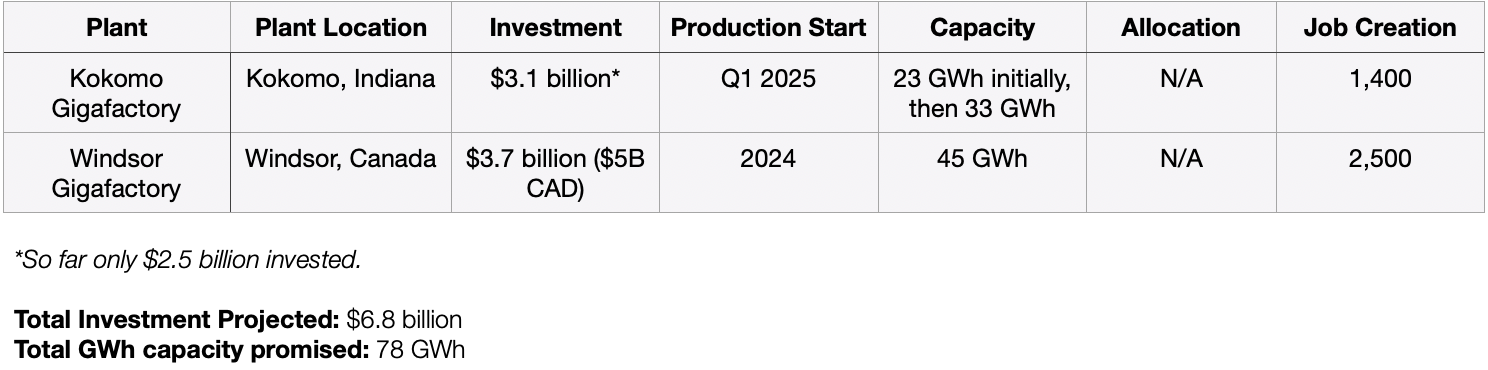

Stellantis

Stellantis and Samsung SDI commenced building on their three way partnership EV battery facility in Indiana in March 2023. The plan for the manufacturing unit is to supply each lithium-ion cells and modules.

Stellantis introduced in July 2023 it might build a second battery factory with Samsung, which can open in early 2027. The automaker didn’t present any additional particulars, like location, GWh capability or what number of jobs the brand new plant will create, so watch this area.

Stellantis, which incorporates manufacturers Alfa Romeo, Chrysler, Jeep and Ram, had introduced a three way partnership with LG in 2021 to construct a North America manufacturing unit with an annual capability of 40 GWh. In March 2022, the 2 firms introduced a binding settlement to take a position (CAD $5 billion) $3.7 billion to supply cells and modules at a producing plant in Windsor, Ontario, Canada.

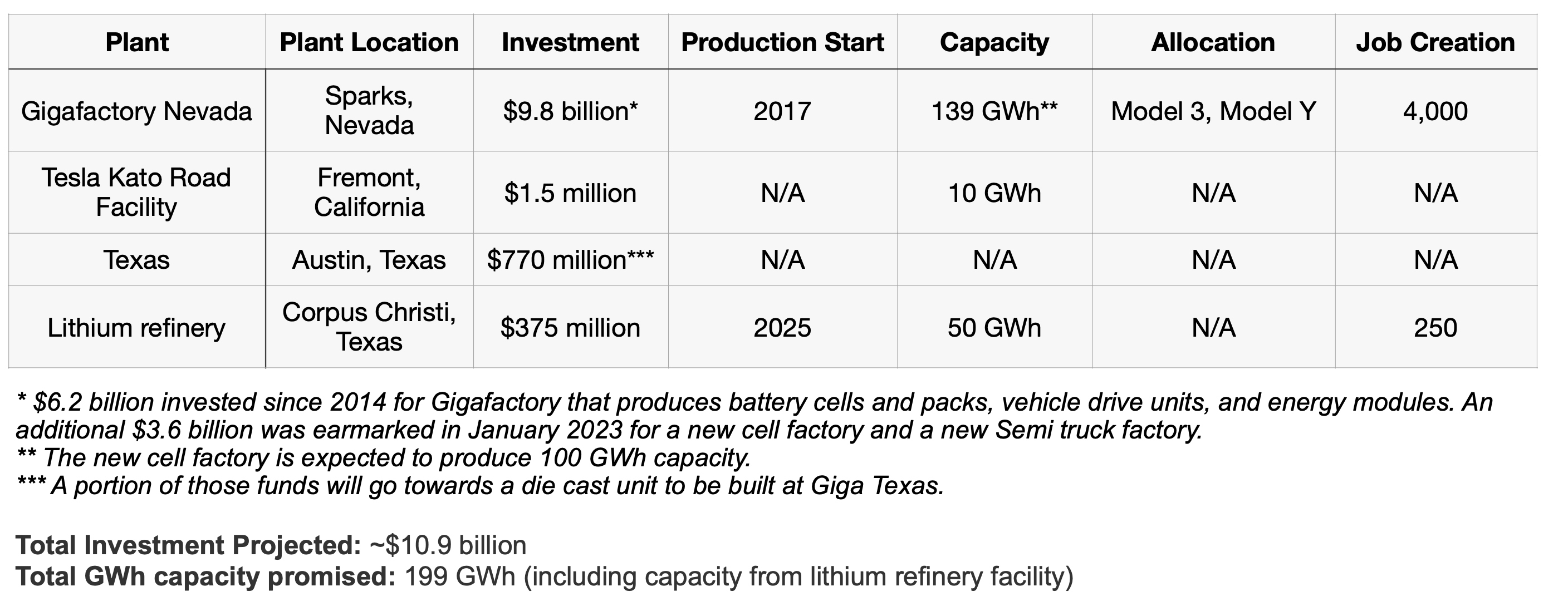

Tesla

Since starting manufacturing at Gigafactory Nevada in 2017, Tesla says it has produced 7.3 billion battery cells and 1.5 million battery packs, which offer about 39 GWh capability yearly, in keeping with Panasonic.

Tesla in January introduced plans to take a position billions extra into the Nevada manufacturing unit to incorporate a brand new 4680 cell manufacturing unit with capability to supply sufficient batteries for 1.5 million mild responsibility autos yearly. 4680 cells, which have been designed by Tesla and revealed at Battery Day 2020, are supposed to cut back battery price by over 50%. Tesla has been making an attempt to get the cells to quantity manufacturing over the previous few years, however has run into roadblocks.

Firstly of 2023, Tesla additionally laid out plans to expand its existing Gigafactory Austin to incorporate battery cell testing and the manufacture of cathode and drive models.

There have additionally been reports of an extension to Tesla’s Fremont, California manufacturing facility to help the manufacturing of the 4860 cell expertise. The automaker has shared few particulars on that extension.

Globally, Tesla additionally deliberate to supply batteries at its Giga Berlin manufacturing unit. Whereas it seems that the power is at present in operation, it’s at a decrease degree than was initially anticipated. The manufacturing unit is at present producing particular person battery parts, however not cells and modules. That work has been despatched to Giga Austin as a substitute, doubtless on account of the IRA incentives.

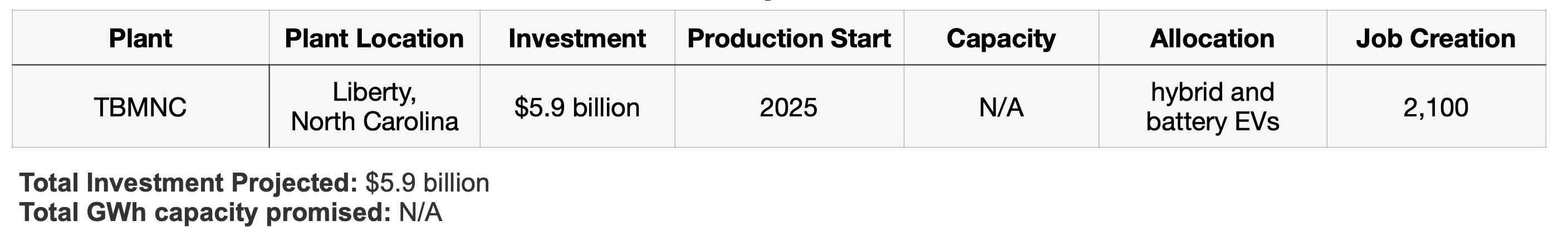

Toyota

Toyota’s deliberate battery plant in North Carolina, initially introduced in 2021, will produce each cells and modules, in keeping with the corporate. When it comes on-line, it’ll have six manufacturing strains, 4 of which can help battery manufacturing for hybrid EVs. The remaining two will help battery EVs.

The Japanese automaker can also be constructing a battery lab at its North American analysis and growth headquarters in Michigan, the place it could actually develop and consider the standard of its EV batteries. The $48 million lab is anticipated to start operations in 2025, and it’ll help the corporate’s manufacturing at factories in North Carolina and Kentucky.

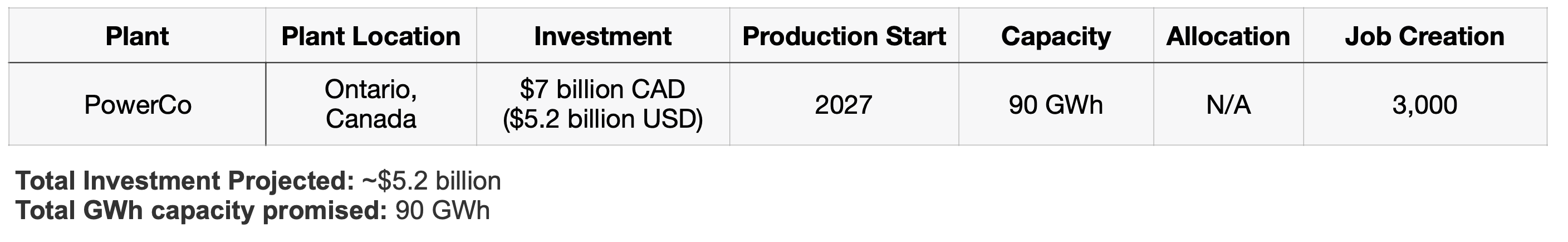

Volkswagen

In July 2022, Volkswagen arrange a separate battery firm, PowerCo SE, to construct batteries for its upcoming EVs. Since its launch, the corporate has selected the placement of three cell factories: Two in Europe (Salzgitter, Germany and Valencia, Spain) and one in North America (St. Thomas, Canada). PowerCo expects to generate an annual income of over 20 billion euros by 2030.

Whereas VW’s battery manufacturing unit is in Canada and never technically within the U.S., it ought to nonetheless be eligible to obtain Inflation Discount Act incentives.

Volvo

Volvo has a battery assembly factory in Charleston, South Carolina, however the automaker doesn’t manufacture batteries or battery parts there. Volvo wouldn’t verify every other plans it has for battery manufacturing in North America.

Battery manufactures constructing in North America

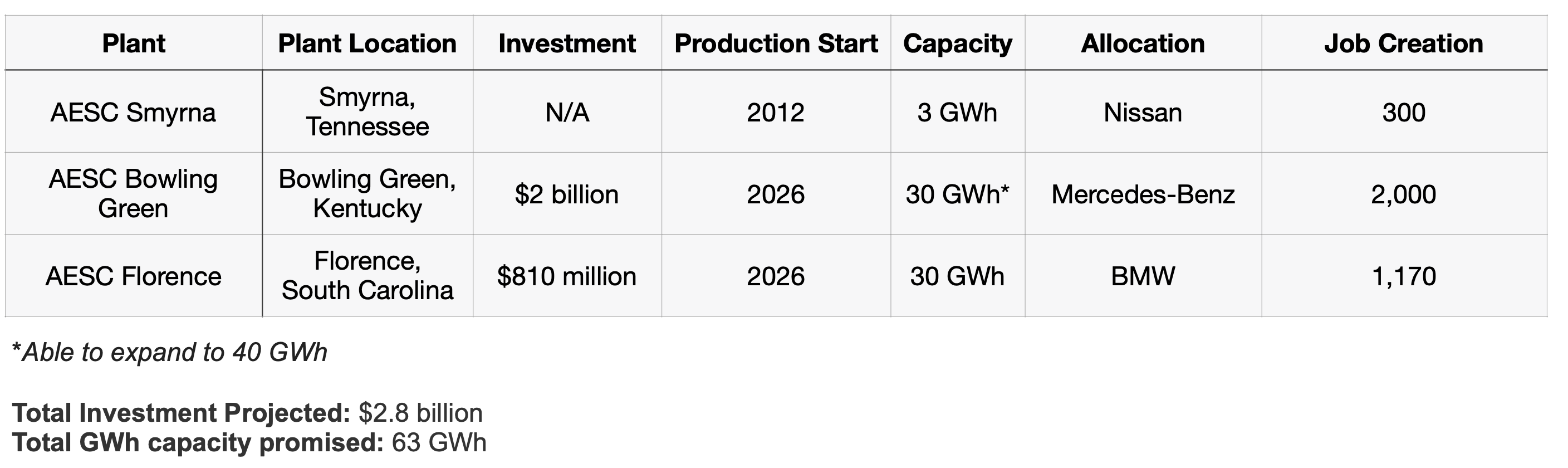

AESC

AESC (previously Envision AESC) is a Japanese battery expertise firm that can have three U.S. services earlier than the tip of the last decade. The corporate’s Tennessee plant has been in operation for a while. AESC broke floor at its Kentucky and South Carolina crops in August 2022 and June 2023, respectively.

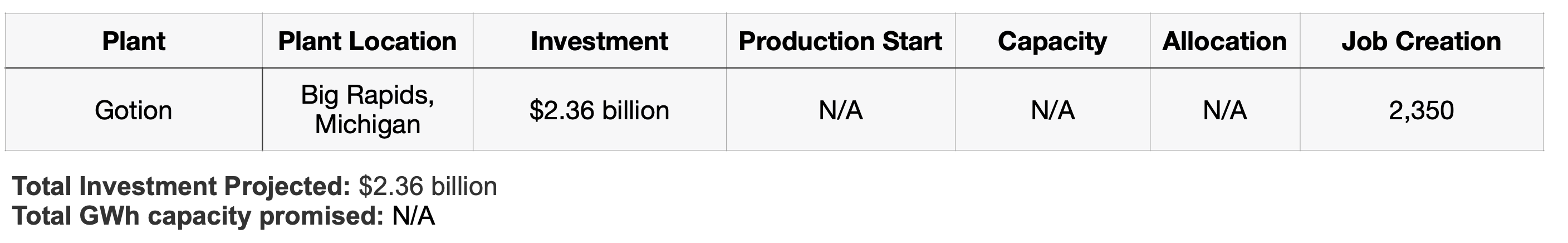

Gotion

Gotion Inc. first introduced its intent to construct a battery manufacturing unit in Michigan in October 2022. The manufacturing unit, which secured $175 million in state funds in April 2023, will construct each cathode and anodes that could possibly be used for each EVs and photo voltaic mills, in keeping with a spokesperson from the corporate.

Gotion is headquartered in Silicon Valley, nevertheless it’s owned by Gotion Excessive-Tech, which is a Chinese language firm.

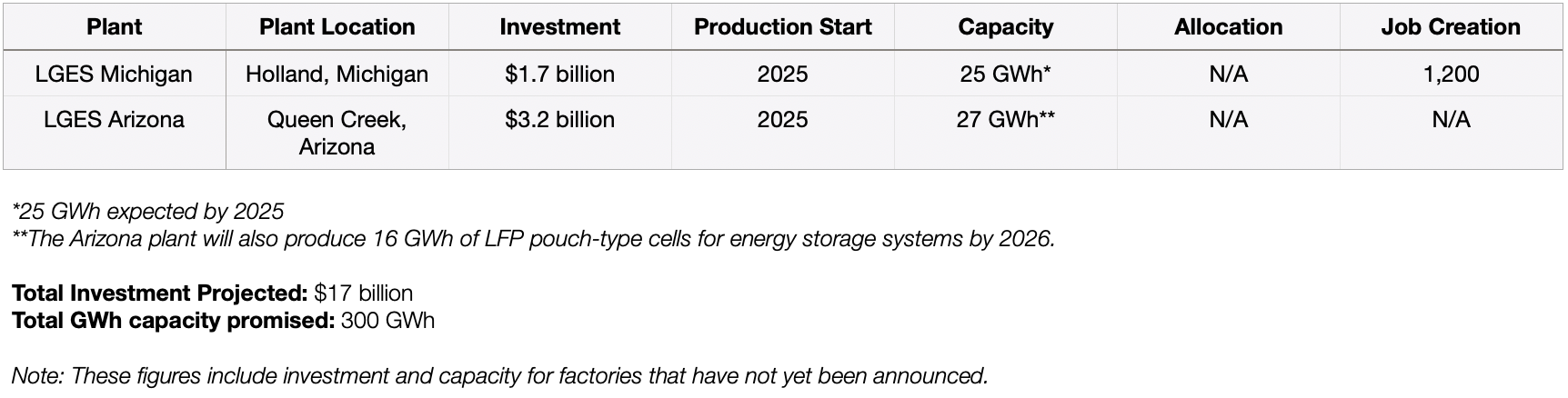

LG Vitality Answer

South Korea’s LG Energy Solution provides EV batteries to automakers like Tesla, Lucid Motors and Proterra. The battery maker has joint ventures to construct battery factories with Normal Motors, Honda and Hyundai, in addition to one with Stellantis in Canada that’s at present on maintain.

In March 2023, LG mentioned it might quintuple the capability of its present lithium-ion cell plant in Michigan, which was inbuilt 2010. LG’s Holland manufacturing unit makes giant polymer battery cells, or pouch sort cells, and packs for EVs. The expanded plant will produce new lengthy cell design batteries, which LG says ought to add extra vary, higher storage, and a extra simplified pack construction.

The battery-maker additionally mentioned it might quadruple its planned investment in a brand new manufacturing unit in Arizona to $5.5 billion, a big portion of which will probably be devoted to EV battery manufacturing. The complicated may have two manufacturing facilities – one devoted to cylindrical batteries for EVs and one other for lithium iron phosphate pouch-type batteries for vitality storage programs.

Most just lately LG announced a building spree in North America, with plans to spend as much as $17 billion by way of 2025 on setting up a complete of eight factories (two of that are already operational) with greater than 300 GWh capability. Whereas the remaining six crops are at varied phases on the way in which to manufacturing, LG has not shared particular particulars.

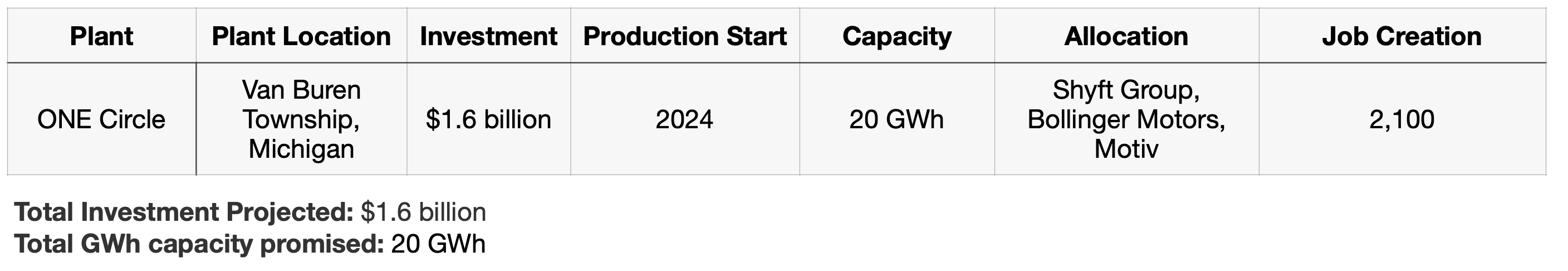

Our Subsequent Vitality

Battery startup Our Subsequent Vitality (ONE) introduced plans in October 2022 to construct a gigafactory in Michigan dedicated to lithium-iron-phosphate cells, AKA LFP batteries. The ability will embody uncooked materials refinement, cathode supplies manufacturing, and cell and battery manufacturing.

To that finish, the corporate just lately raised a $300 million Series B to assist get it to manufacturing.

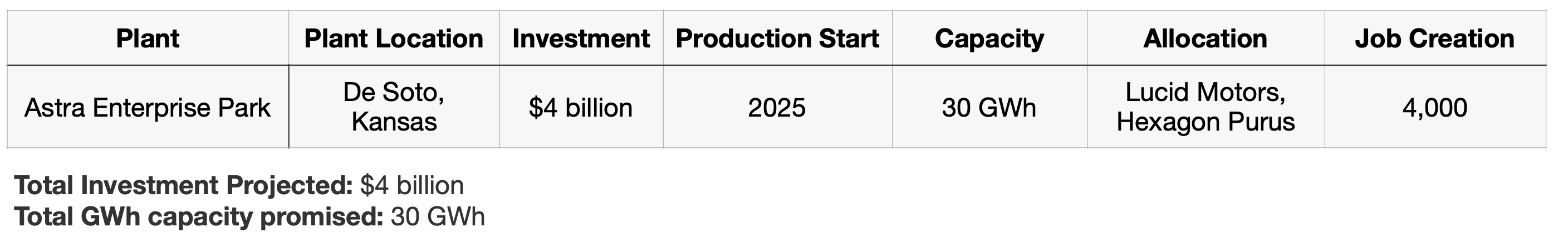

Panasonic

Panasonic mentioned in July 2022 that it plans to construct the world’s largest EV battery plant, a $4 billion manufacturing unit in Kansas that can manufacture and provide lithium-ion batteries to EV makers. The ability in De Soto, Kansas will probably be Panasonic’s second EV battery plant within the U.S. after the Panasonic Vitality of North America (PENA) facility in Sparks, Nevada, which operates inside Tesla’s Nevada gigafactory and provides the EV-maker with batteries.

Panasonic mentioned in June that it plans to develop manufacturing at PENA by 10% inside three years. In Might, the Japanese firm mentioned it might construct at least two new factories for the manufacturing of Tesla 4680 battery cells in North America by 2030. Panasonic goals to decide on its subsequent manufacturing website through the third quarter of 2024.

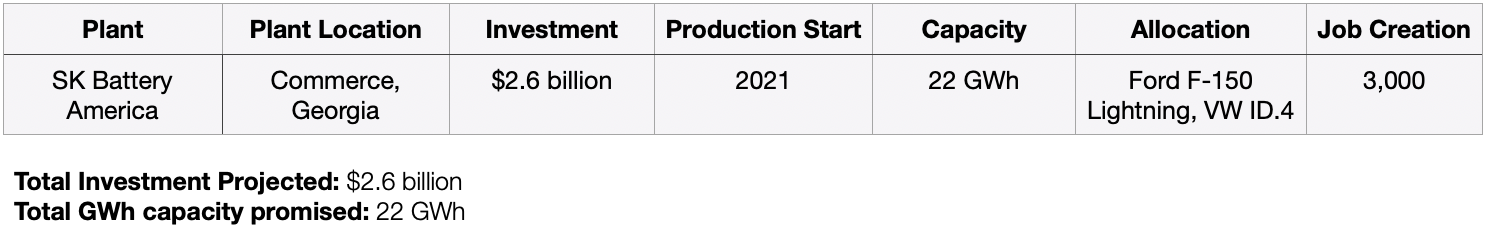

SK Battery America

South Korean battery producer SK On has created joint ventures to develop batteries with Ford and Hyundai. The corporate’s U.S. subsidiary, SK Battery America, has its personal plans.

SK Battery America has invested $2.6 billion into two manufacturing crops in Jackson County, Georgia and reached mass manufacturing in early 2022.

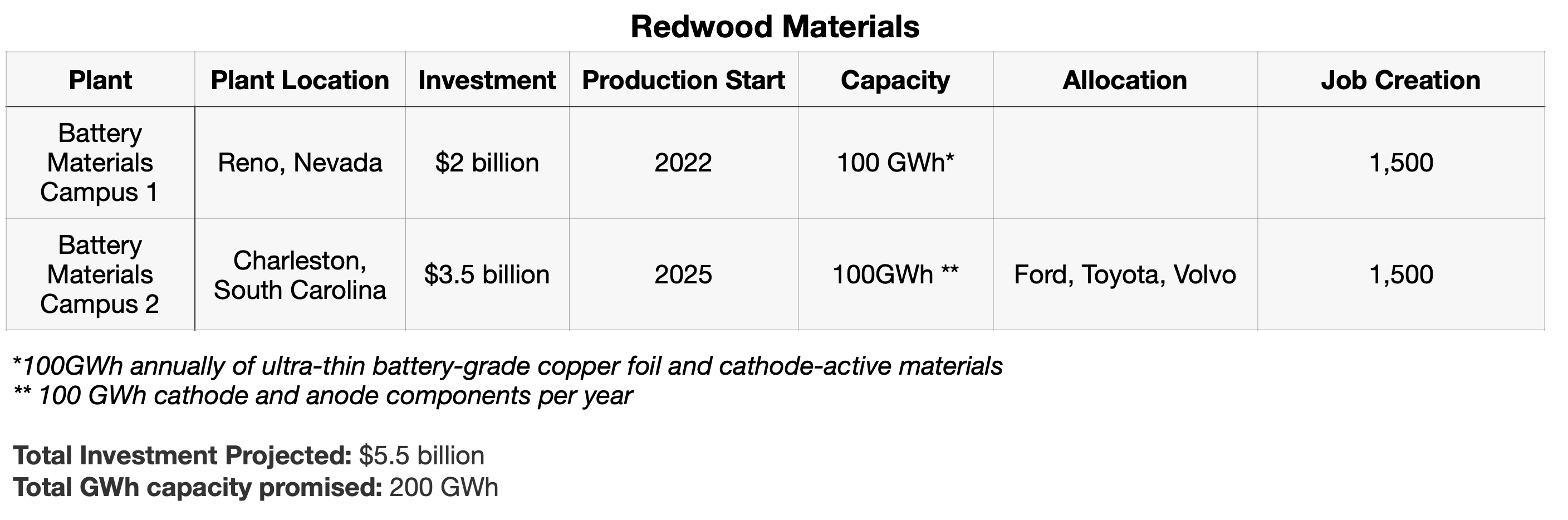

Redwood Supplies

Battery recycling startup Redwood Supplies says its upcoming battery materials campus in South Carolina will recycle, refine and remanufacture cathode and anode supplies reminiscent of nickel, cobalt, lithium and copper. The corporate received’t be producing cells or modules, however it should present a home provide supply to battery makers which can be.

Redwood mentioned its SC plant has the capability to develop to 400 GWh, however that will require a number of billion {dollars} extra of funding. The corporate hasn’t but damaged floor on the location, in keeping with a spokesperson.

Redwood additionally has a northern Nevada plant that produces anode copper foil.

Earlier this 12 months, the startup acquired a $2 billion loan from the DOE to assist it increase its recycling objectives.

[ad_2]

Source link